Good design pops up everywhere.

From the Daily Timewaster, and . . .

From the CLiPS Blog.

From the CLiPS Blog.

Last week I included a reference to Alexander McQueen’s Tattoo Dress in my Tuesday posting. In spite of being a complete fashionista, I was unaware of this designer – even though he did do Whats-her-name’s wedding dress.

Unfortunately, McQueen ended his own life in 2010. I find his designs imaginative and striking . . .

And sometimes, weird . . .

The Tattoo Dress

I am stunned – by this carving of a moose skull and antlers by Shane. Go here to see more of his work.

I thank Rethorykal Questions for this post.

How about this wonderful birdsnest chair bed thingie? It is from OGE Studios and it also comes with white “eggs.” I would go for the Easter egg look, though.

Some tattoos:

If you are still stuck on Star Wars, you can crochet yourself this wonderful Death Star throw pillow (28 inches in diameter). The pattern for the pillow – this one was created in acrylic yarn so you can wash your death star without worrying about shrinkage – is at ravelry.com.

Thanks to Katie for the link.

Also available as a LEGO kit from Amazon for $1,986.49 plus shipping (not eligible for Prime)

More fun stuff:

The June 1952 issue of Popular Mechanics asks the question, “In what kind of house will the captain of a space ship live during his stopovers on earth?” Robert Heinlein, whose Starship Troopers and Stranger in a Strange Land were still in the future, gives a tour of “a house that’s called extreme today but may become conventional before the 20th century has run its course.”

Heinlein described his house as being efficient and easy to clean. Here are a few photos that show some labor saving features:

The commuting table can be set in the kitchen and then rolled into the dining room for meals.

The house had two bedrooms, but all of the sofas pulled out and with pads, could be made into beds.

A hatchway in the kitchen gives access to the trash containers – without ever leaving the room. Actually I have friends who built a similar feature into their kitchen remodel. I’m not sure what is going on in the right hand photo.

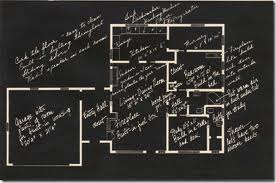

This is a floor plan for the house.

This is a floor plan for the house.

Robert Heinlein, one of the American Masters of Science Fiction, was born today in 1907. Happy Birthday.

The full story of the house that appeared in Popular Mechanics can be found by clicking this link.

Other posts on unusual houses:

This article from American Digest depicts what every kid wants – enough pieces and parts of building toys to make something REALLY BIG.

This is a fantastic marble raceway – and speaking of marbles. Wikipedia provides some insight into their history:

Various balls of stone were found on excavation near Mohenjo-daro. Marbles are also often mentioned in Roman literature, and there are many examples of marbles from ancient Egypt. They were commonly made of clay, stone or glass.

Marbles were first manufactured in Germany in the 1800s. The game has become popular throughout the US and other countries.

Ceramic marbles entered inexpensive mass production in the 1870s.

A German glassblower invented marble scissors in 1846, a device for making marbles. The first mass-produced toy marbles (clay) made in the U.S. were made in Akron, Ohio, by S. C. Dyke, in the early 1890s. Some of the first U.S.-produced glass marbles were also made in Akron, by James Harvey Leighton. In 1903, Martin Frederick Christensen—also of Akron, Ohio—made the first machine-made glass marbles on his patented machine. His company, The M. F. Christensen & Son Co., manufactured millions of toy and industrial glass marbles until they ceased operations in 1917. The next U.S. company to enter the glass marble market was Akro Agate. This company was started by Akronites in 1911, but was located in Clarksburg, West Virginia. Today, there are only two American-based toy marble manufacturers: Jabo Vitro in Reno, Ohio, and Marble King, in Paden City, West Virginia.

And the tattoos:

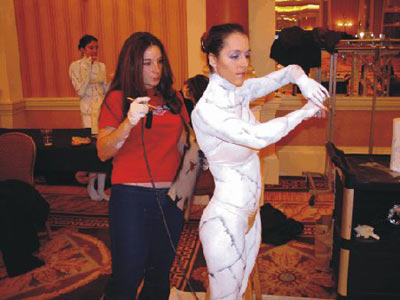

Someone getting airbrushed to look like marble

Someone getting airbrushed to look like marble

– not really a tattoo, but it is in the same vein

Once in a while, a really good design surfaces — robust, simple, and enduring. The DC-3, the Jeep, and the Quonset hut are all examples of good design. Many are still standing throughout the United States, primarily as commercial buildings.

Earlier I wrote about the post-war phenomenon of Lustron Homes. Quonset huts which were ubiquitous during the war were also considered as a solution to the mid-century demand for housing.

This article, Solving a Different Kind of Housing Crisis, discusses the adaptation of Quonset huts for residential use.

As does this article from preservationnation.org.

The quonset hut, whose semi-cylindrical form was copied from the British Nissen hut, by the end of the war differed considerably in construction from its prototype. The original quonset hut was framed with arch-rib members of steel, T sections, 2 inches by 2 inches by 1/4 inch. The hut was 16 feet by 36 feet in plan. The members were formed to a radius of 8 feet and covered with corrugated steel sheets, borne by wood purlins.

The principal improvements over the Nissen type were an interior pressed wood lining, insulation, and a tongue-and-groove wood floor. Innumerable detail problems were encountered in the development of the original T-rib huts, principally because of the necessity for 48 different needs, such as galleys. shower-latrines, dental offices, isolation wards, and bakeries.

Each type required individual drawings and layouts for the interior setup, and in many cases it was necessary to develop special interior equipment, such as special ovens and beds, to fit the quonset hut form. All huts were designed and detailed, using the original T- rib design.

From: The Naval Historical Center

The photo above shows student housing at the University of Colorado in the 1950s.

To meet the growing demand, a number of other companies produced variations of the Quonset Hut for the Military during the Second World War:

- The Pacific Hut Company was formed to produce an all-wood hut for Arctic use.

- Butler Manufacturing made a squat hut with U-shaped arch ribs.

- Jamesway Manufacturing made a hut with wooden ribs and insulated fabric covering.

- Armco International made heavy-weight arched bunkers to store ammunition.

- Cowan and Company made semicircular warehouses for the Air Corp.

When the war ended, Quonset Huts were too good a resource to throw away. So the military sold them to civilians for about a thousand dollars each. They made serviceable single-family homes. Universities made them into student housing and returning veterans occupied Quonset huts by choice. Robert Winton even wrote play about them titled Tents of Tin.

Finally, here’s a little animation about putting a Quonset hut together.

There are still a number of Quonset huts around and in use as commercial buildings in the Connecticut Western Reserve area where I live. I am going to go out with my camera to capture them.

Just about anything would be better than a FEMA trailer, but look at this from Preservation Nation. It is an article about Lustron pre-fabricated homes . . .

“They were literally building the American dream.

In the late 1940s, soldiers returning from World War II dreamed of the idyllic life: a happy family, a lovely suburban home. But the post-war period instead brought a housing crisis. In response, Lustron promised a dream house — signed, sealed, delivered.”

I think these homes are a wonderful example of mid-20th century style, design and ingenuity. It’s like IKEA for the 50s.

“It has a sort of late ‘40s, ‘50s new modern America appeal,” says Megan Wood of the Ohio Historical Society. “And you don’t have to paint it, you can clean the walls with windex, and you can hang things with magnets.”

I think it is interesting that out of 3000 homes built, about 1500 still survive, including the one pictured above, that is in Indiana.

I think these houses are charming and it is unfortunate that dodgy financing forced the company into bankruptcy in 1950.

I am Lego-loving this representation of each of the fifty states created in Lego. It is from Buzzfeed, via Robb, via Regan. Mui gracias!